by Sharon Volpes

Diffusion phenomena are omnipresent in nature, playing key roles in various fields ranging from physics to biology. Though Fickian diffusion is well-known to most of us, these phenomena can exist in other forms and are generally called anomalous types of diffusion. One of the most intriguing examples of anomalous diffusion is so-called “Case II” diffusion occurring in glassy polymer matrices.

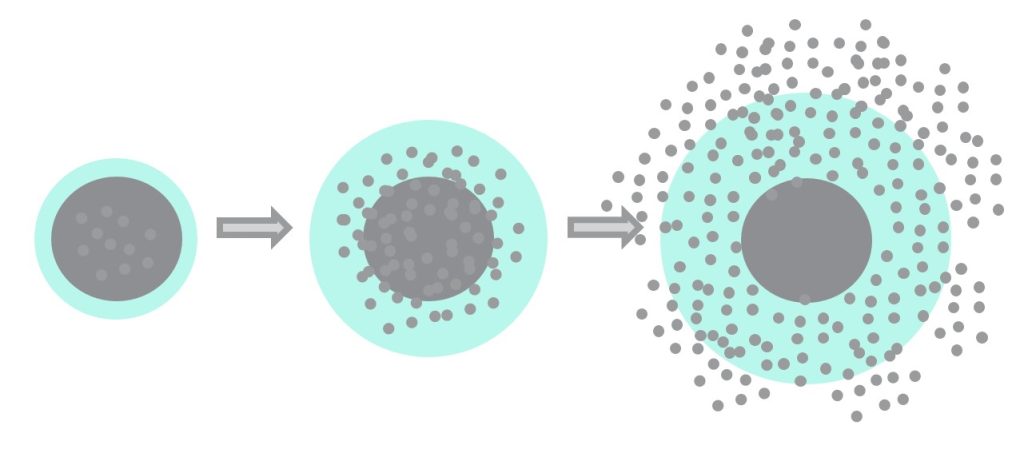

Unlike the well-known Fickian diffusion, which does not present a real boundary between the two mixing species, Case II diffusion exhibits a sharp diffusion front moving at a constant velocity. In fact, the rate of diffusion is not solely determined by the concentration gradient, but is also influenced by the relaxation and swelling of the polymer matrix, leading to the anomalous transport phenomena.

This phenomenon finds diverse applications in various fields, for example drug delivery and food packaging, offering opportunities to enhance the efficacy and safety of products. In drug delivery, Case II diffusion holds promise for controlled release formulations. By carefully engineering polymer matrices with specific swelling properties, researchers can tailor drug release profiles to achieve sustained therapeutic effects [1].

In the field of food packaging, Case II diffusion offers innovative solutions for extending shelf life and preserving product quality. By incorporating polymers with controlled swelling properties into packaging materials, manufacturers can create barriers that regulate the exchange of gases such as oxygen and moisture [2]. This helps prevent oxidation, microbial growth, and moisture loss, thereby prolonging the

freshness and safety of perishable foods. Moreover, Case II diffusion enables the development of active packaging systems capable of releasing antimicrobial agents, antioxidants, or flavoring agents in a controlled manner [3]. This not only enhances food preservation but also enriches the sensory experience for consumers.

While Case II diffusion holds great potential, its implementation requires a multidisciplinary approach encompassing materials science, engineering, and pharmacology. As part of my project we investigate the diffusion of solvents in glassy polymer films through Molecular Dynamics simulations, observing Case II diffusion. Through simulations, we can get insights into the microscopic mechanism behind this phenomenon, which is fundamental for tailoring materials with precise diffusion properties.

In conclusion, the exploration of Case II diffusion for practical applications presents an opportunity to make use of any exceptions in order to facilitate innovation and advancement in different areas. By making use of unexpected behaviors of substances in non-typical scenarios, we create new possibilities in the materials field, drug delivery systems and more. Indeed, daring the unusual may open up pathways towards the ground-breaking solutions of tomorrow.

References

[1] Serra, L., Doménech, J., & Peppas, N. A. (2006). Drug transport mechanisms and release kinetics from molecularly designed poly(acrylic acid-g-ethylene glycol) hydrogels. Biomaterials, 27(31), 5440-5451. https://doi.org/10.1016/j.biomaterials.2006.06.011

[2] Suppakul, P., Miltz, J., Sonneveld, K., & Bigger, S. W. (2003). Active packaging technologies with an emphasis on antimicrobial packaging and its applications. Journal of Food Science, 68(2), 408-420. https://doi.org/10.1111/j.1365-2621.2003.tb05687.x

[3] Bastarrachea, L. J., Dhawan, S., & Sablani, S. S. (2011). Engineering properties of polymeric-based antimicrobial films for food packaging: a review. Food Engineering Reviews, 3(2), 79-93. https://doi.org/10.1007/s12393-011-9034-8